Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

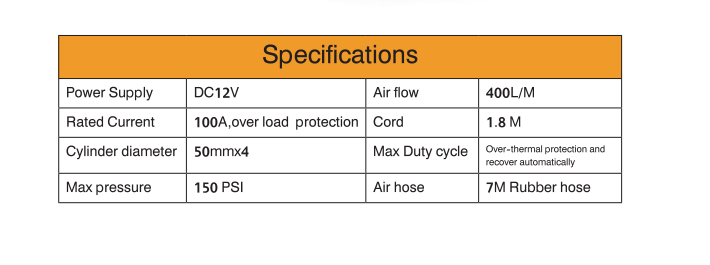

| Power Supply | DC12V | Air flow | 400L/M |

| Rated Current | 100A,over load protection | Cord | 1.8M |

| Cylinder diameter | 50mmx4 | Max Duty cycle | Over-thermal protection and recover automatically |

| Max pressure | 150 PSI | Air hose | 7M Rubber hose |

Auto-Cross country —— The best choice for field sport. WORKER is a highly specialised winch manufacturer situated in Ningbo, Zhejiang province, the most developed area in Changjiang, now the economic hub of China. Our premises cover an area of 16000 square meters, comprising more than 15,500 square meters of factory floor space and offices for our 100-plus employees. Our manufacturing plant has state-of-the-art assembly lines, together with in-house precision die-casting, CNC machining, heat treatment, polishing, high-pressure cleaning and finishing facilities.

We also have the most advanced, fully-automated intelligent electric motor and winch testing facilities in the winch industry, to ensure the very highest standards of product reliability and durability. Established in 2005,WORKER began a highly progressive and intensive R & D programme into winch design, using the very latest in technology, to improve product performance and efficiency in production. We currently own patents on our many improved winch design features and strive to maintain our unsurpassed build-quality and outstanding value.

Today, WORKER has a comprehensive range of winch products and is developing more, including the first in a series of efficient hydraulic winches, for the commercial and military markets. Our factory is currently producing 100,000 winches a year making us the one of the largest winch manufacturers in China. Winches which are exported to Europe, North America, Australia and many other countries, both in the guise of our own brand as well as OEM’s for many top names. Our philosophy is simple; to stay ahead in our business by being totally professional, but have fun doing it by remaining young in our hearts and minds.

We have passed CE CERTIFICATE, TUV CERTIFICATE, IATF 16949 CERTIFICATE, ISO14001:2015 CERTIFICATE and ISO9001:2000 CERTIFICATE.

Parts assembly - Finished product assembly - Inspection and testing - Packing into boxes

We support sea, air and land transportation, delivery to door point (refer to WE COULD BY SEA OR AIR OR DOOR TO DOOR SHIPPING). Products are generally shipped within 35 days, according to the product to provide bubble and carton packaging to ensure product safety.

Q: What is the MOQ?

A: Each product has different requirements, please contact us for specific products.

Q: What is your delivery time?

A: 35-40 days

Q: What is the payment method?

A: 30% PAYMENT AFTER CONFIRMED THE ORDER, 70% PAYMENT WHEN WE ARE READY TO SHIP.

Q: How do you guarantee the quality of the products?

A: We have strict factory testing to ensure the quality of each product.

Q: Are you a factory or a trading company?

A: The integration of industry and trade.

Q: Where is your factory?

A: Ningbo, if you want to visit, you can contact us.

Q: Are customized services available?

A: As long as you tell us your needs, we will provide you with customized solutions.

Q: Do you support OEM and ODM?

A: We support OEM and ODM services, if you need, you can contact us.

Q: Why choose us?

A: We are a professional manufacturer, focusing on the manufacture of 4*4 auto parts.

Strict inspection and testing process to ensure the quality of each product.

High-quality after-sales service to solve every problem related to auto parts.

Q: How long is the product warranty period?

A: 1-3 years.

No matter how advanced the vehicle is, if it doesn't work properly, it can't realize its full potential. This is why we provide wk-102-45 air compressor for off-road vehicles. This product allows all your components to easily maintain the highest level of performance and is designed for trucks and other high-performance machines. In addition to ensuring that you have a good time outside, this air compressor also ensures that you always have an a + riding experience. Use WK-102-45 to ensure smooth operation of your vehicle.

Wk-102-45 air compressor is most suitable for off-road, dune truck and dune truck. It operates on a 12 volt power supply. Corrosion resistant powder coating design is adopted to improve durability. Carbon steel finned rotating blade motor can achieve long life and high performance. Precision CNC processed castings have excellent adhesion and function, durable thermoplastic resin shell, etc.

Be easy to carry about

Easy to store. Special handle, easy to carry.

Anti slip and wear resistance

Wear resistant rubber pad on the surface to protect the air pump from damage.

Multifunctional

Sufficient accessories for different purposes

Convert Presta valve to Schrader Valve: first remove the bicycle cup and then screw the adapter onto the thread of the valve stem.If you want to modify a wheel, what should you know first?

A lot of people think that as long as the wheel is bigger, just change the wheel. After all, it looks good. But it often has drawbacks. Disadvantages will be discussed later. First, let's talk about how to choose a hub and what process to choose. At present, the mainstream process wheels on the market include low pressure casting, spinning and forging. At present, most workshops do not have gravity technology, and most of them do not have gravity technology on the market. Let's talk about the differences and craftsmanship of these wheels.

Low pressure casting wheels

As we all know, low pressure casting is to set the mold, then pour the aluminum liquid into the mold, and then apply a certain pressure to make the internal molecules more compact. This is low pressure casting. At present, almost all cars on the market use wheels. Because the price is high, the production is good, and the price is cheap and affordable.

Spinning hub

Spinning is actually a relatively complex process in low-pressure casting, and it is also produced by low-pressure casting. However, part of the rim is heated by the spinning machine as it is rotated and punched. This increases the molecular density of the rim, making the corresponding rim more rigid. Therefore, many car owners currently choose to rotate the wheel hub. Of course, forging is too expensive. Spinning is somewhere between casting and forging, offering both cost-effectiveness and performance. Currently, the price of spinning wheels is also in between. Likewise, the swivel hubs use the same A356 cast aluminum as low pressure casting.

Forged Wheels

Forged wheels are different from the aluminum used in both of the above. Use 6061 forged aluminum. In terms of rigidity, it is like the difference between the iPhone 6 and the iPhone 6s in previous years. One is curved. Forged wheels not only have advantages in terms of aluminum and rigidity, but the weight is also the reason why many people choose it. Lightweight means lower fuel consumption and better body handling. On top of that, forging supports customization. You can do whatever you like. Engineers draw the drawings upon request, and then perform milling on forged aluminum blanks. The first two are not supported. After all, no manufacturer will reopen the mold. This is why forging is expensive.